PBS & PBAT Production Machinery | At DT Int’l Group, we take pride in being your one-stop destination for all your biodegradable material production plant needs. With years of experience and expertise in the industry, we offer comprehensive services that encompass every stage of the process. We commit to providing top-notch solutions for the production of biodegradable materials, specifically focusing on PBS (Polybutylene Succinate) and PBAT (Polybutylene Adipate-co-Terephthalate), from design and manufacturing to supply, installation, startup, and training.

Our PBS & PBAT Production Services

- Design: Our skilled team of engineers and experts will work closely with you to create a tailor-made design that aligns perfectly with your production requirements. Whether you need a small-scale facility or a large industrial plant, we cover you.

- Manufacturing: As specialists in biodegradable material production, we utilize state-of-the-art technology and adhere to the highest industry standards to manufacture top-quality PBS and PBAT production equipment. Our focus on precision and efficiency ensures reliable and consistent performance.

- Supply: We understand the importance of timely supply in the production process. You can count on us to deliver the necessary equipment and materials promptly, ensuring minimal downtime and smooth operations.

- Installation: The installation process will be handled by our experienced team, ensuring the correct setup and integration of every component into your production plant. Rest assured that our installation services are efficient and meet the highest safety standards.

- Startup: The successful startup of your production plant is critical to its performance. Our experts will be there to guide you through this phase, ensuring a seamless transition and optimal functioning of the equipment.

- Training: To maximize the potential of your biodegradable material production plant, we offer comprehensive training programs. Your team will receive hands-on training and in-depth knowledge about the equipment, processes, and safety protocols.

Why Choose Us for PBS & PBAT Production?

- Expertise: Our team comprises skilled professionals with extensive experience in the biodegradable material production industry.

- Quality: We are committed to delivering high-quality equipment and services that meet international standards.

- Customization: We design every plant to suit your specific production needs and goals.

- Reliability: Our track record of successful installations and satisfied clients speaks for itself.

- Sustainability: By focusing on biodegradable materials like PBS and PBAT, we contribute to a greener and more sustainable future.

If you are ready to embark on a journey toward a more sustainable production process, look no further than DT Int’l Group. Get in touch with us today to discuss your biodegradable material production plant requirements, and let’s work together to create a cleaner and greener world. Request a Free Quote.

Technical Background of PBS

As concerns over white pollution and the non-renewable energy crisis grow more severe, the development and utilization of biodegradable plastics have emerged as an effective solution. Among these biodegradable plastics, PBS stands out as a leader due to its excellent biodegradability and heat resistance.

PBS Industrialization Project

In 2002, the Chinese Academy of Sciences (CAS) listed the industrialization project of PBS as an innovation project. Subsequently, in 2005, they recognized PBS as one of the key issues in environmentally friendly materials. The government has placed a strong focus on promoting the industrialization of PBS.

Quality Index of PBS

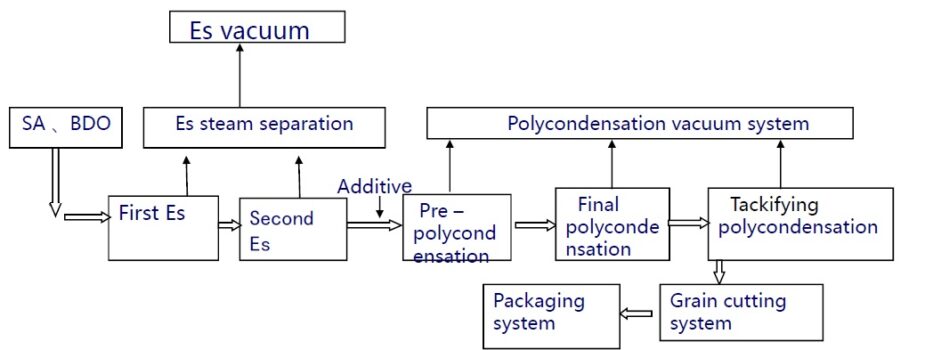

We prepare our PBS (Polybutylene Succinate) from 1,4-succinic acid (SA-1,4) and 1,4-butanediol (BDO) through continuous esterification and polycondensation processes.

Quality Index:

- Density: 1200~1280kg/m3

- Average Molecular Weight: ≥150,000

- Melt Index: ≤10g/10min

- Intrinsic Viscosity: ≥1.8dL/g

- Melting Point: 110~130℃

Characteristics and Applications of PBS Products

PBS can be derived from either petroleum resources or the fermentation of biological resources. Its remarkable heat resistance allows products made from PBS to withstand temperatures exceeding 100℃.

Moreover, PBS is easily decomposed and metabolized by various microorganisms and enzymes in nature, ultimately breaking down into carbon dioxide and water.

Applications of PBS:

- Widely used in everyday life

- Agricultural materials, including agricultural film, pesticides, and slow-release fertilizers

- Biomedical polymer materials

PBS & PBAT Production Plant Process Brief

Our advanced PBS Production Machinery Plant follows a streamlined and efficient process, ensuring top-quality biodegradable material production. The production line features a setup of five reactors in series, all designed to achieve outstanding results:

- Vertical Esterification Reactors with Agitator: The first step involves two vertical esterification reactors featuring agitators for optimal mixing. This crucial stage sets the foundation for the subsequent processes.

- Falling Film Tower Pre-polycondensation Reactor: Next, the pre-polycondensation reactor, utilizing a falling film tower design, further refines the materials, preparing them for the final stages of production.

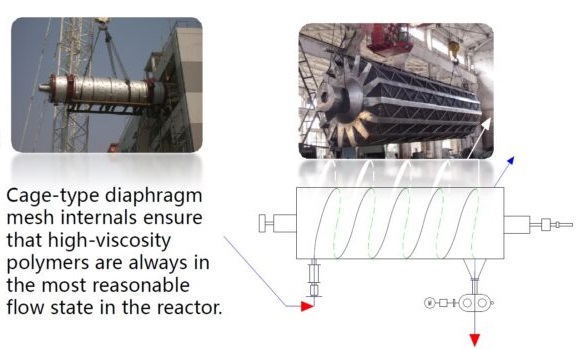

- Cage-frame Final Polycondensation Reactor: Within the cage-frame reactor, the polycondensation process reaches its pinnacle, resulting in the formation of high-quality PBS biodegradable material.

- Horizontal Single/Double-Axis Tackifying Polycondensation Reactor: The last reactor in our production line employs a horizontal single/double-axis tackifying polycondensation design, adding the finishing touches to the PBS biodegradable material.

PBS & PBAT Production Machinery Key Equipment

Cage-Type Final Polycondensation Reactor

Single/Double-Axis Tackifying Polycondensation Reactor

In a single/double-axis reactor, the melt forms a film between rotating gears. Simultaneously, small molecule BDO is continuously removed under high vacuum conditions, leading to a further condensation reaction. This process results in the product achieving higher viscosity.

Recovery of By-Product

Recovery of THF from Esterification Wastewater

During the esterification stage, the production of PBS generates a byproduct called tetrahydrofuran (THF) from BDO. Subsequently, this THF is carried along with the esterification vapor into the separation tower, where it is then extracted from the esterification water. To maximize resource utilization, we have implemented a specialized tetrahydrofuran recovery unit to reclaim THF efficiently from the esterification water. As a result, the recovered THF holds valuable applications as a solvent or can serve as a raw material for various organic synthesis processes. This eco-conscious approach not only ensures optimal production efficiency but also promotes sustainable practices within our PBS Petrochemical Production Plant.

With our well-engineered and meticulously designed production line, we ensure the efficient and reliable manufacturing of PBS, a leading biodegradable material that aligns perfectly with environmentally conscious goals.

Join us in our commitment to sustainability and eco-friendly solutions. Contact us to explore how our PBS & PBAT Petrochemical Production Plant can cater to your biodegradable