At DT Int’l Group, we specialize in providing high-quality biodegradable PLA and PBAT pellets, offering sustainable solutions for industries worldwide. With years of experience and a commitment to sustainability, we cater to various industries’ needs with premium pellets, granules, and resins.

Our Biodegradable Products: PLA, PBAT, and PBS Pellets

Biodegradable PBS Pellets: Applications and Benefits

PBS, or Polybutylene Succinate, is a versatile thermoplastic polyester with a milky white appearance. It has no odor or taste and exhibits remarkable mechanical properties and exceptional thermal resistance. As a result, it is ideal for biodegradable solutions in packaging, agriculture, and more.

One of the key features of PBS is its high thermal deviation temperature, which makes it suitable for applications involving varying temperatures. Additionally, PBS demonstrates excellent biocompatibility and efficient bioabsorption. Microorganisms, plants, and animals can easily decompose in natural environments. Over time, PBS breaks down into harmless substances like carbon dioxide and water, contributing positively to the environment.

In the realm of polymer materials, PBS stands out as a 100% biodegradable polymer. Its biodegradability makes it a key player in the global push for environmentally friendly materials.

Applications of Biodegradable PBS Pellets:

PBS finds widespread use in diverse industries, including injection molding, tableware production, cup covers, fiber manufacturing, and packaging films. Moreover, it has established a significant presence in sectors like agriculture and medicine due to its unique properties.

Packaging:

• 25kg /bag, liner: PE/Alu

• 800kg /bag, liner: PE/Alu

Typical Basic Material Properties of PBS:

| Item | Unit | Value |

| Density (25 °C) | g/cm3 | 1.25 ± 0.03 |

| Melting Point | °C | 105~116 |

| Melt Flow Rate | g/10min | ≤10 10-20 20-40 |

| Moisture Content | % | ≤0.1 |

| Color L Value | – | ≥75 |

| Color A Value | – | ≤5 |

| Color B Value | – | ≤10 |

| Carboxy End Groups | mol/t | ≤50 |

| Tensile Strength | MPa | 25 |

| Break Elongation | % | 150 |

| Flexural Strength | MPa | 25 |

| Flexural Modulus | MPa | 400 |

| Ash | % | ≤0.1 |

Eco-Friendly PBAT Pellets for Sustainable Packaging

Polybutylene Adipate-co-Terephthalate (PBAT) is a biodegradable copolymer with excellent compostability and flexibility. Industries widely use it in packaging, agricultural films, and other environmentally friendly applications.

PBAT is a biodegradable aliphatic-aromatic copolymer. After modification, manufacturers can apply it to the blown film process. Typical products include supermarket shopping bags, garbage bags, garment bags, and industrial packaging.

Packaging:

• 25kg /bag, liner: PE/Alu

• 750kg /bag, liner: PE/Alu

Storage:

During transportation and storage, the temperature should not exceed 55℃. Unopened products can be stored for up to 12 months at room temperature (23℃).

Shelf-Life:

For granules, we recommend using PBAT immediately after opening the package. If customers partially use the product, they should reseal the bag properly and use it as soon as possible.

Typical Basic Material Properties of PBAT:

| Property | Unit | Test Method | PBAT |

| Mass Density | g/cm3 | ISO 1183 | 1.23 ± 0.02 |

| Hardness | HA | ISO 868 | 90 ± 2 |

| Tensile Strength | MPa | ISO 527 | ≥ 22 |

| Elongation At Break | % | ISO 527 | ≥ 600 |

| Notched Impact Strength | Kj/m2 | ISO 179 | ≥ 20 |

| Melt Flow Rate MFR (190°C, 2.16kg) | g/10 min | ISO 1133 | ≤ 5 |

| Melting Points | °C | ISO 3146 | 121 ± 2 |

| Vicat Softening Temperature/A50 | °C | ISO 306 | 94 ± 1 |

| Thermal Decomposition Temperature | °C | ASTM D6370 | 360 |

| Moisture | % | ISO 15512 | ≤ 0.1 |

| Ash Content | % | ISO 3451 | ≤ 0.1 |

Versatile PLA Pellets for Biodegradable Solutions

Polylactic Acid (PLA) is a versatile bioplastic derived from renewable resources. Industries commonly use PLA pellets, granules, and chips in 3D printing, food packaging, and single-use disposables.

PLA resin has broken the plastic processing industry’s dependence on traditional petroleum-based resins and has realized the vision of originating from nature and returning to nature.

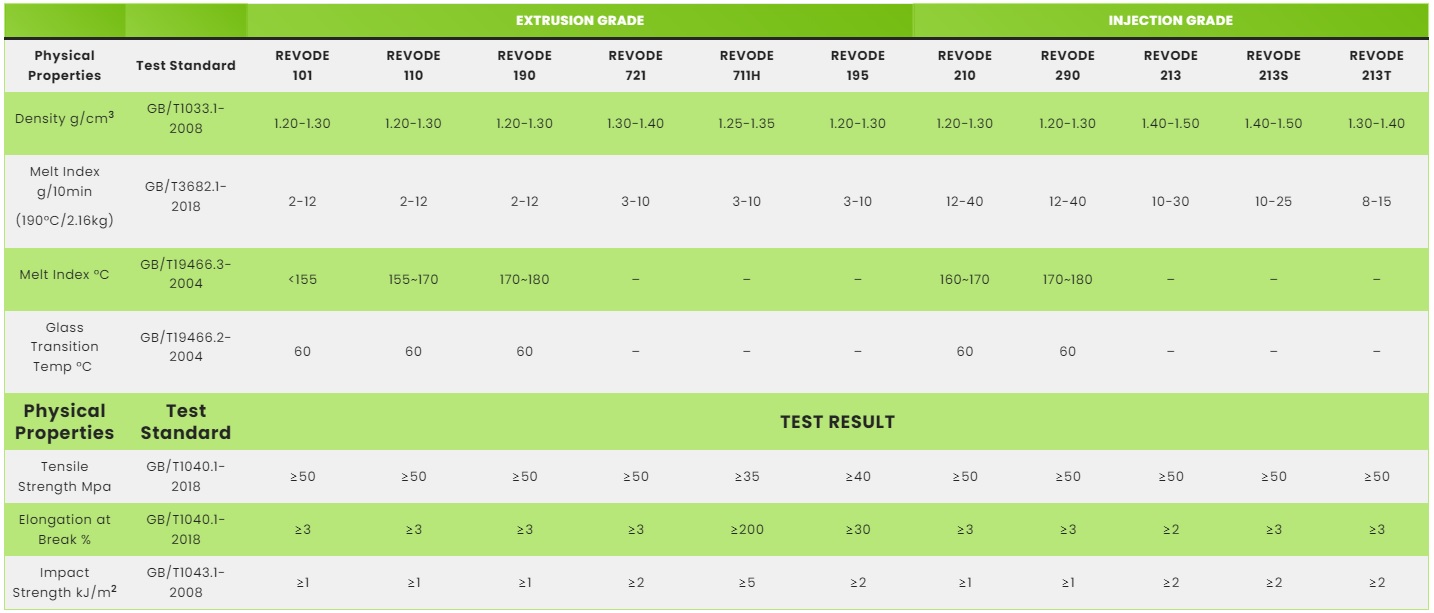

Extrusion & Thermoforming:

– Applied to extrusion products

REVODE101: Its transparency, glossiness, and mechanical properties are similar to those of PET, but its toughness is inferior to that of PET. It is easy to color and print, so it can be used in traditional extrusion equipment.

REVODE110: It has excellent transparency and processability, suitable for transparent extrusion products.

REVODE190: It has higher optical purity than REVODE110 and is suitable to be use as a base material of high-end extrusion-use compounds.

– Applied to straw extrusion

REVODE711H: It is a kind of toughened compound that is specially designed for straw extrusion.

REVODE711B: It is a kind of toughened compound with excellent flexibility, which is specially designed for straw extrusion.

Injection:

– Applied to injection molding products

REVODE210: It has excellent transparency and processability, suitable for transparent injection molding products.

REVODE290: It has higher optical purity than REVODE210 and is suitable to be use as a base material for high-end injection molding compounds.

REVODE213: It is a kind of heat-resistant PLA compound that is suitable for highly heat-resistant disposable injection molding products.

REVODE213S: It is a kind of heat-resistant PLA compound that has a high gloss after crystallization through a special process. It is suitable for the processing of high-end injection molding products.

REVODE701: It is suitable for processing injection products that have a high demand for toughness.

REVODE713: It is a kind of toughened PLA compound with better toughness than REVODE701 and is suitable for injection molding products with higher toughness.

Film:

– Applied to blown film, laminating film, and stretch film products

REVODE101: It has excellent transparency and processability, and lower optical purity than REVODE110. It is suitable for processing products requiring high heat sealing properties, such as cast film, or as the base material for blowing film compounding.

REVODE110: It has excellent transparency and processability, suitable for casting film or as the base material for blowing film compounding.

REVODE110/190: It has excellent extrusion processability, suitable for laminating processing.

REVODE101/110/190: It has excellent extrusion processability, suitable for biaxially oriented film processing.

Fiber/Non-woven:

– Used for fiber processing, including monofilament, composite filament, spun bond, and melt-blown non-woven products.

– Amorphous and crystalline grades with melting points ranging from 130℃ to 180℃.

REVODE101: It is used for the production of composite skin core fibers. And suitable foran adhesive layer for heat-sealing products.

REVODE110: It has excellent fiber processability, suitable for processing staple fibers, non-woven fabrics, and other fiber products.

REVODE190: It has excellent fiber processability, suitable for processing fiber products with low shrinkage and high dimensional temperature stability.

REVODE210: Suitable for processing melt-blown nonwovens.

Extrusion/Injection Blowing:

– Applied to extrusion/injection blowing products

REVODE110: Suitable for processing transparent non-heat-resistant extrusion blowing, injection blowing products.

REVODE219C: It is a kind of heat-resistant compound whose properties are near to PCTG.

3D Printing:

– Applied to 3D printing filament

REVODE110: It has excellent transparency, low warping, and high-level adhesion, suitable for 3D printing filament processing or as the base material of 3D printing compounding.

REVODE190: It is a basic material specially designed for 3D printing compounding. Properties are similar to REVODE110, melt point is higher than that of REVODE110.

REVODE195: It is a kind of toughened PLA compound that is suitable for processing 3D printing products with high toughness.

Properties of PLA:

Why Choose DT Int’l Group:

- Premium Quality: We manufacture our products using the latest technology and ensure they meet international quality standards, delivering consistent performance.

- Sustainable Solutions: We actively promote eco-friendly alternatives and develop biodegradable materials that help create a cleaner and greener planet.

- Customization: We offer a wide range of pellet/granule/chip sizes to meet your specific production requirements.

- Global Reach: With a well-established supply chain, we cater to customers worldwide, providing timely and reliable deliveries.

- Expert Support: Our team of experts is always ready to assist you with product selection and technical guidance.

Industries We Serve:

- Packaging

- Textile and Apparel

- Agriculture

- Food Service

- Medical and Healthcare

- Consumer Goods

Contact Us: For inquiries or to place an order for PBS, PBAT, or PLA Pellet/Granule/Chip/Resin, please reach out to our sales team at [email protected]. We look forward to being your trusted partner in sustainable biodegradable materials.

Join us in our mission to create a greener and more sustainable future. Together, let’s make a positive impact on the environment with biodegradable solutions from DT Int’l Group.